In the realm of manufacturing, the convergence of efficiency and precision is paramount. Tube and plate laser cutting machine are at the forefront of this technological revolution. These cutting-edge devices, renowned for their versatility and accuracy, have redefined the landscape of metal fabrication and various industries, offering unparalleled capabilities in shaping and transforming materials.

The Fusion of Technology

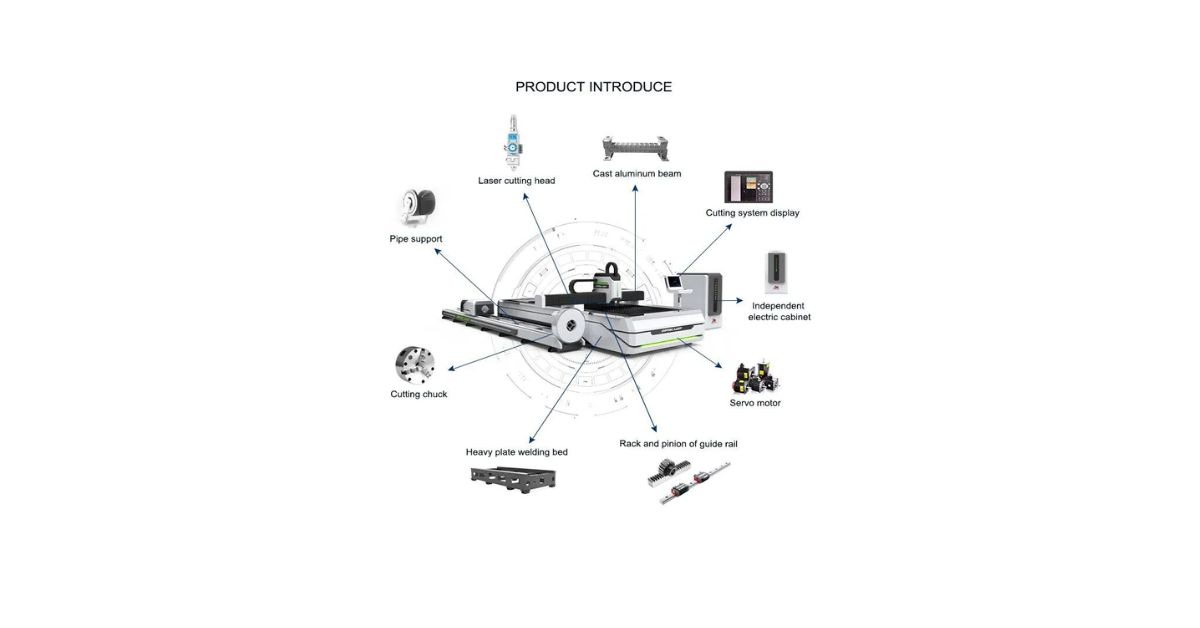

Tube and plate laser cutting machines are a marvel of technological innovation, harnessing the power of laser beams to slice through various materials precisely. These machines’ ability to handle flat plates and cylindrical tubes with equal finesse distinguishes them. Chinese manufacturers, in particular, have spearheaded advancements in this realm, engineering machines that seamlessly cater to diverse cutting needs.

Versatility Unleashed

One of the defining features of these machines is their adaptability. Traditional cutting methods often struggle with the intricacies of curved surfaces or the complexities of varying thicknesses, but tube and plate laser cutting machines navigate these challenges effortlessly. Their capability to slice through a spectrum of materials, including stainless steel, aluminum, and alloys, while maintaining precision across different shapes and sizes makes them indispensable across multiple industries.

Unparalleled Precision and Efficiency

Precision is the hallmark of these machines. The focused laser beam ensures accuracy within micrometer tolerances, enabling intricate designs and precise cuts that would be unattainable through conventional methods. This level of precision enhances the quality of the end product and reduces material wastage, contributing to cost-effectiveness.

Furthermore, their efficiency is unmatched. The high-speed cutting capabilities of these machines streamline production processes, leading to shorter lead times and increased output. Whether it’s intricate components for aerospace engineering or structural elements for architectural projects, the speed and accuracy of tube and plate laser cutting machines elevate manufacturing to new heights.

Technological Advancements and Challenges

Continuous technological advancements remain pivotal for these machines to stay ahead in an ever-evolving landscape. Innovations in beam quality, power output, and automation are ongoing endeavors to enhance their capabilities further. Challenges persist in optimizing these machines for cost-effectiveness while maintaining quality, particularly in a fiercely competitive global market.

Future Prospects and Global Impact

The future holds immense promise for tube and plate laser cutting machines. Integrating artificial intelligence and machine learning into these systems is on the horizon, promising greater automation, efficiency, and predictive maintenance. Moreover, their global influence continues to grow as industries worldwide recognize the transformative potential of these machines in streamlining production and enhancing product quality.

Conclusion

Tube and plate laser cutting machines stand as a testament to human ingenuity, marrying precision and versatility in a manner that revolutionizes manufacturing. Their ability to effortlessly navigate various materials and shapes, coupled with unmatched accuracy and efficiency, cements their position as indispensable tools across industries. As technological advancements continue to unfold, these machines are poised to remain at the vanguard of modern manufacturing, shaping the future of metal fabrication and beyond.